FORD LABORATORY TEST METHOD BO160-04

详细信息

| | 品牌:德国walter | | 型号:LTA1 | | 加工定制:否 | |

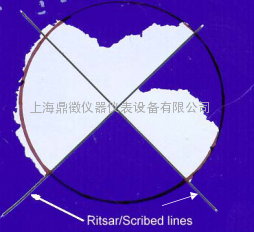

| | 类型:蒸汽喷射 | | 材质:不锈钢 | | 温度范围:0-100 ℃ | |

| | 功率:100 W | | 工作室尺寸:400x500x600 mm | | 电源:400V | |

| | 适用范围:汽车零部件涂料 | | | | | |

FORD LABORATORY TEST METHOD

BO 160-04

Application

This procedure defines the test equipment and test method for the resistance of painted plastic parts (e.g., bumper bars, mirror housings, radiator grills) against high pressure cleaning processes.

Equipment Required

High Pressure Cleaning Equipment:

Cleemax serial 1053

Source:

Pearson Panke Equipment Ltd,

1-3, Hale Grove Gardens,

London NW7 3LR

Great Britain.

Or equivalent instrument suitable to provide the required temperature, pressure and flow rate of water, with a fixed or moving head.

Jet type QVVA 2506

Scriber type:

See FLTM BI 106-1

Settings –

Method A, fixed jet:

| Jet position |

Perpendicular to specimen |

| Water temperature |

70 °C +/- 2 °C |

| Distance of nozzle to specimen |

50mm +/-3mm |

| Water pressure |

3000 +/-50 kPa |

| Testing time |

60 +/- 3 seconds |

| Water flow rate |

420 litres/hour minimum |

Method B, moving jet.

| Jet position |

Perpendicular to specimen |

| Water Temperature |

80 °C +/- 4 °C |

| Distance of nozzle to specimen |

100 mm +/-3mm |

| Water pressure |

6000 +/-50 kPa |

| Moving range |

30mm +/- 10 mm from center,total traverse 60mm |

| Moving cycle |

60 cycle/minute |

| Moving direction |

parallel to the X scribe on the specimen |

| Jet position |

Perpendicular to specimen |

| |

(The lines of the X scribe are Northeast to Southwest. The longer axis of the spray fan pattern is East-West, and the direction of movement is North-South.) |

| Testing time |

120 seconds, +/-3 seconds |

| Water flow rate |

610 litres/hour minimum |

| Note: The water pressure and water temperature settings must be measured immediately behind the nozzle |

Conditioning and Test Conditions

All test values indicated herein are based on material conditioned in a controlled atmosphere of 23 +/- 2 °C and 50 +/- 5% relative humidity for not less than 24 h prior to testing and tested under the same conditions unless otherwise specified.

Procedure

1. The equipment is filled with water without any additional cleaning agents and heated.

2. Before testing the equipment must be adjusted to the required test pressure for the specified distance.

3 Scribe the panel with an X scribe, over the whole area to be exposed to the water jet.

4. The gun with the nozzle is fixed to the required distance from the nozzle to the painted surface which is to be tested. The jet of water has to be directed vertically onto the painted surface.

5. Spray water for the specified length of time.

6. The surface is dried and evaluated after cooling to 23 +/- 2 °C.

7. Report any failure (e.g., loss of gloss, loss of adhesion, surface deterioration). The principal failure mode is paint peeling.

Chemicals, materials, parts, and equipment referenced in this document must be used and handled properly. Each party is responsible for determining proper use and handling in its facilities.

上海鼎振仪器设备有限公司

上海鼎振仪器设备有限公司 扫一扫,手机浏览

扫一扫,手机浏览