- 技术文章

DIN50018在含有二氧化硫的大气环境下的冷凝水一交变气候中的试验

2025-03-01 17:43:02 来源:上海鼎振仪器设备有限公司

1、Purpose and range of application 适用范围和目的.

This standard describes the general condition which must be observed for testing samples in condensation atmosphere containing sulphur dioxide, so that comparable results are obtained when the test is carried out in different laboratories.

本标准描述了必须符合测试样品要求的含二氧化硫浓缩气氛一般情形,以便在不同实验室获得的试验结果可比较。

The test allows defects in corrosion protection systems to be detected quickly. Exposure to these test atmospheres does not allow any direct conclusions to be drawn regarding the life of the tested components under practical duty conditions. This, however, does not exclude the possibility, once ample experience has been gained regarding the long-term behaviours of specific systems in an industrial atmosphere, of being able to establish a relationship between the behaviour in practical service and the behaviour under test conditions, particularly in atmosphere DIN 50 018 – SFW0.25.

该试验可以很快发现在腐蚀保护系统里的缺陷,暴露在这类试验气氛下,不能得出任何关于试验对象实际应用寿命的直接结论;但也不排除这种可能,即在获得关于在工业气氛下的特定系统的长久性能的足够经验后,能够确定实际应用性能和试验性能之间的关系,尤其是在DIN 50 018 – SFW0.25的气氛下。

It is advisable to test only identical corrosion protection system simultaneously in one and same test facility, since the possibility of interaction between samples representing different system cannot be excluded.

由于代表不同系统的样品之间影响的可能性不可避免,同时在一个测试设备对仅有同样的防腐处理系统进行试验是可行的。

When different corrosion protection systems are tested simultaneously and different materials are present, it should be borne in mind that different effects are often brought about by sulphur dioxide. Direct comparison of the results of tests on different combinations of corrosion protection systems and materials is therefore not readily permissible.

当不同腐蚀保护系统同时被测试,我们应知道,二氧化硫气氛经常会有不同的试验结果,一般不能直接比较腐蚀保护系统下的不同化合物和材料的试验结果。

Sample form, sample preparation, test duration, evaluation of the test and assessment of the results are not the subject of this Standard. Details on these points will be found in the relevant Standards or special specifications, or are to be agreed case by case. In particular, the remarks in DIN 50 905 part 1 to part 3 are to be observed when carrying out this test.

样品形状,样品准备,试验持续时间,评估试验和试验结果,都不是本标准的主题,在别的标准或专门的技术规范里可以找到这些方面的详细资料,或者一次次试验后得到认可。特别的情况,按DIN 50 905 部分1 to 部分3的说明进行试验。

2、Other relevant Standards(相关标准)

DIN 50 900 Part 1 Corrosion of metals; definitions, general definition.

金属腐蚀,定义,一般定义

DIN 50 900 Part 2 Corrosion of metals; definitions, electrochemical definition.

金属腐蚀,定义,电化学定义

DIN 50 900 Part 1 Corrosion of metals; chemical corrosion tests, general.

金属腐蚀,化学腐蚀试验,概要

DIN 50 900 Part 2 Corrosion of metals; chemical corrosion tests, corrosion values with uniform surface corrosion.

金属腐蚀,化学腐蚀试验,均匀腐蚀表面的腐蚀数据

DIN 50 900 Part 3 Corrosion of metals; chemical corrosion tests, corrosion values with non-uniform corrosion absence of additional mechanical stress.

金属腐蚀,化学腐蚀试验,没有附加机械应力的不均匀腐蚀表面的腐蚀数据

3、Definition (定义)

According to DIN 50 900 Patr1 and Part2.

按照DIN 50 900 1部分 and 2部分

4、Test condition

at the star of the first test phase in each cycle the test chamber temperature is raised to ±31℃ over a period of about 1 1/2 hours. At the same time condensation forms on the samples. This wetting must persist throughout the further progress of the first test phase. It is during this stage that the test reaches maximum everity through the the simultaneous action of sulphur dioxide.

每个循环的一试验阶段开始时,在1.5小时内把测试室温度调到±31℃,同时,对样品进行浓缩,其湿度应能保持整个试验阶段一。通过SO2的同时作用,在试验阶段达到*大 。

Note: the sulphur dioxide admitted at the start of the first test phase quickly dissolves to a great extent in the water in the bottom of the test chamber. At the start of the test, therefore, the effective sulphur dioxide concentration in the gas space is only about 1/7 of theoretical concentration. This initial concentration does not remain constant during the first phase, but instead drops sharply at first and thereafter more slowly.

注意:SO2应在试验开始阶段确认已经*大程度溶解到测试室底部的水里,因此,在试验开始时,空间的浓缩SO2的作用只有理论浓度的1/7。这初始的浓度不会在一阶段的试验中一直保持不变,而是刚开始下降很快,后面变慢。

The second test phase starts with the disconnection of the heat supply and the opening or ventilating of the test chamber, which must lead to the establishing after about 1 1/2 hours of the test conditions according to the Table.

试验第二阶段,停止加热打开测试室通风,按下表实验条件1.5小时后即可。

*Usually known abroad under the old designation RRSt 1405.Type of test condition

试验条件Theoretical SO2 concentration start of a cycle

循环开始时理论的SO2浓度

% by vol.(体积百分比)0.067* 0.33* 0.67* Condensation atmosphere(浓缩气氛) DIN50 018-SFW0.2S DIN50 018-SFW1.0S DIN50 018-SFW2.0S Cycle Test phase 1 h

试验阶段18 including heating

8小时(含加热时间)Test phase 2 h

试验阶段216 including cooling

16小时(包含冷却时间)

(test chamber opened ventilate)实验室要通风Total h

总共24 Conditions in test space

试验室条件Test phase 1 Temperature ℃ 40±3 Relative humidity% Approx. 100(wetting of test specimens)

大约100(试验样品湿度)Test phase 2 Temperature ℃ 18 to 28 Relative humidity% Max.75 Water quantity in the test space % by vol.

试验室水含量 体积百分比0.67 - For a test facility with a test chamber volume of 300l,the theoretical so2 concentration corresponds to an so2 admission per cycle of 0.2l, 1.0l, 2.0l.

- For a test facility with a volume of 300l, this concentration corresponds to a quality of 2l 测试室体积为300L的设备,相应SO2浓度是2L

*通常国外在旧RR标准 1405以下。

5、Test facility(试验设备)

5.1 Test chamber(测试室)

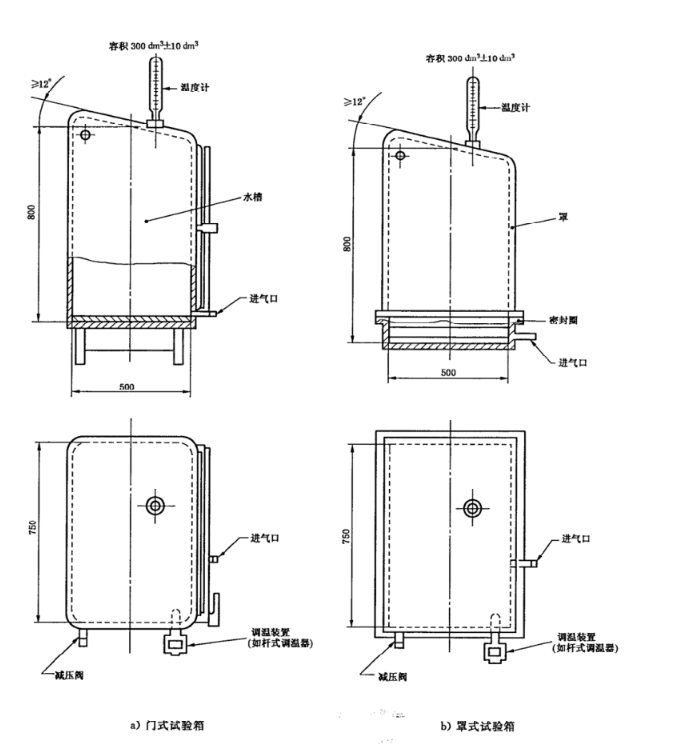

Testing in a warm humid atmosphere containing sulphur dioxide requires a test chamber with a volume of at least 300L closed all round and sealed and having walls consisting of a corrosion-resistant material which, moreover, must not influence the corrosion. The test chamber must have a bottom trough capable of being heated and of holding the quantity of water prescribed in the Table. The heating of the test chamber takes place only via this water bath.

在温热潮湿含SO2气氛下试验,需要一个至少300L封闭的并有防腐蚀壁的容器,而且,不能影响腐蚀。测试室必须有能加热和容纳表中所要求的水用量的底槽,加热就是通过测试室底槽水浴进行的。

A suitable temperature measuring and control device must be available in the test chamber. The temperature is measured in the immediate vicinity of the samples. The valves necessary for pressure equalization and the gas inlet must be located above the water surface. The roof of the test chamber must be so constituted as to prevent condensate from dripping down on to the samples. The shape and size of the test chamber are optional, provided that the requirements of Section 5 and 7 are fulfilled. The illustration shows a test facility with a chamber volume of 300L.

测试室要有温度测量和控制装置,温度要靠近样品测量,压力调节阀和进气阀必须装在水面以上,测试室顶必须这样设计,是为了防止冷凝物滴到样品上。测试室的形状和尺寸是可选的,只要符合第5、7节的要求。图中所示即为300L的测试室。

The test chamber is to be set up in a room without corrosive atmosphere, at room temperature and a relative humidity not exceeding 75%, and so installed that it is protected from draughts and sola irradiation.

测试室装在没有腐蚀气氛的房间里,在室温下,相对湿度不超过75%,这样安装是为了防止气流和阴极放射。

5.2 Sample holder(样品固定器)

the sample holder must consist of a corrosion-resistant material which also must not influence the corrosion of the sample. it must be so constituted that the samples can be arranged to suit the requirements of Section 6.2.

样品固定器要有防腐蚀材料,同样,该材料不能影响样品腐蚀,样品应符合6.2节的要求。

6 Procedures(程序)

6.1 Samples (样品)

Only samples which do not affect each other should be tested jointly.

不会相互影响的样品方可一起试验。

6.2 Arrangement of samples(样品准备)

The samples are to be so arranged in the test chamber that the following spacing is maintained: 在测试室的样品按以下位置要求准备。

Distance from walls at least 100mm

距离测试室壁 至少100 mm

Distance of underside of samples from surface of water at least 200mm

样品下表面离水面距离 至少200mm

Distance between samples at least 20mm

样品间距 至少20mm

In the absence of any agreements to the contrary, the total surface area of the suspended samples should amount to 0.5m2 ±0.1 m2 per 300L of test chamber volume. Special agreements are to be made in respect of samples the surface area of which cannot be determined.

必须满足试验要求,每个300L的测试室里,悬挂样品的总表面积为0.5m2 ±0.1 m2,无法测量的样品表面积可以特许。

It is importance to ensure that during exposure no condensate can drip on to the samples. Since the same amount of sulphur dioxide is affective in each cycle, the result depends on the size and nature of the total sample surface area loaded. For comparative tests it is therefore indispensable to work each time with the same total sample surface area and samples of like a kind.

样品放进测试室后,务必确定没有冷凝物滴到样品上,由于每个循环同样量的SO2作用,结果就取决于放进去的样品表面的尺寸和性质。为了试验的可比较,要使每次的试验样品总面积相同样品类型相同。

It is also important that the material used to mask surface which are not to be exposed should be of a kind which does not reach with sulphur dioxide and also does not influence the test result in any other way.

还有一点很重要,就是用来保护其它表面的材料应同类型,不与SO2反应,也不能在任何方面影响试验结果。

6.3 Filling the bottom trough(底部水槽加水)

The bottom trough should be filled with the quality of distilled or deionized water stated in the Table. Prior to each cycle the water must be renewed and the test chamber cleaned if necessary.

底部水槽按表中要求加蒸馏水或去离子水,每次循环前要更新水,必要时清洗测试室。

6.4 Gas supply(供气)

Before the sulphur dioxide is admitted the test chamber must be closed.

SO2气体导入前应关闭测试室。

6.4.1 Supplying sulphur dioxide from steel cylinders. For the exact measurement of the amount sulphur dioxide admitted, commercial-type gas meters or containers with fluid displacement(paraffin oil) may be used.

从钢瓶加SO2气体,为了加入正好需要的气体量,应该用气体压力表或有流体置换器(石蜡油)的容器。

6.4.2 Generation of sulphur dioxide inside the test facility.

在试验设备里SO2产生

It is also permissible to generate sulpur dioxide inside the test facility by suitable means(e.g. NaHSO3+dilute sulphuric acid)

也可以在试验设备里通过合适的方法制备SO2气体(例如:NaHSO3+稀硫酸)

6.5 Heating(加热)

the heating should be switched on immediately after the admission of sulphur dioxide and the test chamber raised to temperature of 40℃ over a period of about 1 1/2 hours. This temperature must be held to within ±3℃ at the measuring point.

SO2气体加入后立即开始加热,使测试室在1.5小时内升温到40℃,在测试点上该温度应保持在±3℃内。

6.6 Test duration(测试持续时间)

If the specific test Standards do not lay down any test duration,1,2,5,10 or 20 cycles should be run for preference. The test may be broken off any unacceptable impairment of the appearance or function of the samples occurs or if a given degree of corrosion is reached.

如果专门的测试标准没有制定任何试验持续时间,可以持续1,2,5,10或20个循环,试验在以下情况结束:样品外观或功能出现了不希望的损伤,或达到了试验设定的腐蚀程度。

6.7 Test sequence(试验顺序)

Each cycle comprises two-test phase corresponding to the Table, i.e. totaling 24 hours. At the end of the first test phase(8 hours)the heating is switched off and the test chamber opened or ventilated.

每个循环包含两个对应于表的测试阶段,即总计24小时。一阶段(8小时)结束后,停止加热,打开测试室通风。

At the end of the second test phase (18 hours) the bottom trough is emptied, cleaned if necessary, and filled with fresh distilled or deionized water. The test chamber is then closed and solphur dioxide admitted. With the switching on of the heating a new cycle starts.

第二阶段(18小时)结束后,底部水槽应清干,必要时清洗,重新加蒸馏水或去离子水。关闭测试室导入SO2,打开加热开关开始新的循环。

6.8 Interrupting the test(试验中断)

Test interruptions are to be made up by prolonging the second test phase and are to be indicated in the report. When specimens are to be exposed to only 1 or 2 cycles, the test facility should have been in operation beforehand for at least 1 cycle.

延长第二阶段试验时,试验应中断并在报告中简要说明。当样品只是暴露1或2个循环,测试设备至少应在1个循环前开始运行。

7. Functional check of the test facility

测试设备功能检验

For monitoring the reproducibility the test results given by a test facility, or those of identical test facilities at different locations, it is necessary to carry out a functional check at appropriate intervals. Test facilities with a test chamber volume of 300L are covered by the provision in Sections 7.1 to 7.8.

为监测测试设备的在再现性,或这些同样的设备在不同地点,就有必要在适当间隔后检验测试设备功能。有300L测试室的测试设备在7.1到7.8节有说明。

7.1Test material 测试材料

7.1.1 Five samples each measuring 50mm wide, 100mm long and 0.6 to 1.5mm thick, of the steel grades St 37(bright as rolled) to DIN 17 100 or St 1405° (bright as rolled) to DIN 1623 part 1 ground with a ceramic wheel of hardness J and 46 grit.

5个50 mm宽,100 mm长,0.6~1.5mm厚的样品同时测试,钢材等级标准37(亮度如金箔),在DIN 17 100 or 标准 1405, DIN 1623 部分 1,硬度等级J和46筛网陶瓷地面。

7.1.2 Two blank samples each measuring 250mm wide,400mm long and 1mm thick, of the steel grades St 37(bright as rolled) to DIN 17 100 or St 1405°)(bright as rolled)to DIN1623 Part1.

两个空白样品,250mm 宽,400mm 长,1mm 厚,

7.2 Sample preparation(样品准备)

Before the functional check is started, the test material according to Section 7.1 should be degreased by using white spirit or another suitable solvent applied with a soft lint-free cloth or a brush, and the sample according to Section 7.1.1 then weighed to the nearest 1 mg. If the weighing cannot be performed immediately after degreasing, the sample should be kept in a desiccator until weighed.

开始功能检验前,符合7.1节规定测试材料应用石油溶剂进行脱脂处理,或其它合适的溶剂,用不含麻的软布或刷子处理,符合7.1.1节规定的样品称重精确到1 mg。如果脱脂后不能立即进行称重,在称重前样品应保存在干燥器里。

7.3 Performance of the functional check

进行功能检验

The five samples according to Section 7.1.1 are arranged vertically in the chamber. The blank samples according to Section 7.1.2 are also arranged vertically on either side of five samples according to Section 7.1.1. The exposure of the samples extends over five cycles corresponding to the test conditions SFW 0.25 according to Section 6.

7.1.1所说的5个样品在测试室垂直放置,7.1.2规定的空白样品也垂直放置在7.1.1所说的5个样品的另一边,样品将在6规定的测试条件下暴露5个循环以上。

7.4 Removing the corrosion products(清除腐蚀产物)

On completion of the functional check the corrosion products are removed from the samples by using an approximately 10% solution of hydrochloric acid(230ml of chemically pure HCLρ=1.18g/ml and 730ml of distilled or deionized water), to which 0.1% properly alcohol has been added, at room temperature. After the corrosion products have been removed, the samples are thoroughly rinsed in distilled or deionized water, dried and then kept in the desiccator at room temperature from 18 to 28℃ until weighed.

完成功能检验后,用大约10%的盐酸溶解(230ml 化学纯的 HCL ρ=1.18g/ml 加730ml 的蒸馏水或去离子水),从侵蚀样品清除侵蚀产物,加0.1%酒精,在室温下。侵蚀产物清除后,样品放在蒸馏水或去离子水里彻底清洗、干燥,称重前保存在干燥器里,室温18到28℃下。

7.5 Weighing the samples(称重)

The samples are weighed to the nearest 1mg.

样品称重精确到1 mg。

7.6 Evaluation of results(评估结果)

The

-

上海鼎振仪器设备有限公司

上海鼎振仪器设备有限公司咨询热线 13472521719 内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。上海鼎振仪器设备有限公司 电话:021-32535039 手机:13472521719 地址: 上海市嘉定区德富路1198号803室太湖世家国际大厦

扫一扫,手机浏览

扫一扫,手机浏览