- 技术文章

PV3932植绒耐磨试验标准

2019-09-11 08:06:06 来源:上海鼎徵仪器仪表设备

Changes The following changes have been made as compared to Test Specification PV 3932: 1996-07:─ Section 1.2: Requirement according to TL 52345 for elastomer parts added

─ Section 2: Parameters of abrasion chisel for elastomers added

─ Section 3: Dimensions for specimens removed

─ Section 5: Bearing weight of chisel changed; total stroke count for elastomers according to TL 42345 added

Previous issues 1996-07

1 Scope

This Test Specification is used for first-sample tests and for standard production monitoring tests. The test is performed to simulate the flock abrasion while in use and serves to evaluate the quality of the materials used (substrate, plastic, and flock material), the flocking process, and any substrate pretreatment that might be required.

2 Requirements ─ For plastic parts: See Technical Supply Specification TL 52447 or drawing ─ For elastomer parts See TL 52345

3 Test equipment

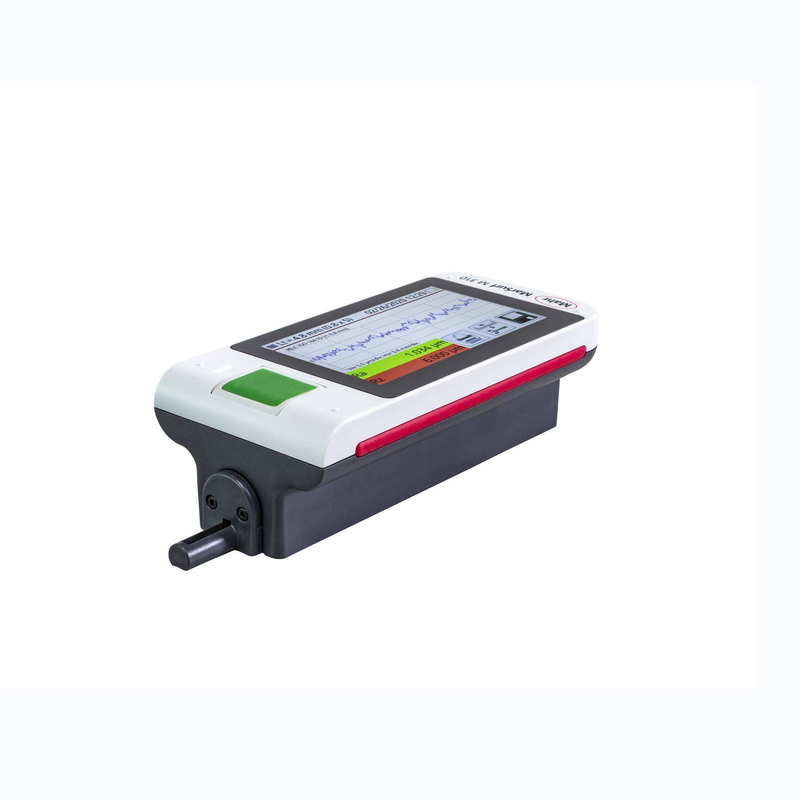

Abrasion tester: APG 1000 made by Maag Flockmaschinen or similar device Abrasion chisel: Width 20 mm, radius R = 0,50 mm, hardened steel (for plastics) Width 2,8 mm, radius R = 0,16 mm, hardened steel (for elastomers)

4 Specimens

The specimens are prepared from finished parts.

5 Specimen pretreatment

The specimens must be aged for a minimum of 24 h in the DIN 50014-23/50-2 standard climate.

6 Procedure

The specimen is securely clamped in a clamping bar on a sled. The abrasion chisel is then attached and loaded with a weight. The bearing weight of the chisel on the specimen surface is 750 g per cm of chisel width. The edge of the chisel must be guided parallel to the specimen surface. The sled velocity is set such that 60 double strokes/min are produced. The required total stroke count for plastic parts is 500 double strokes. For elastomer parts, see TL 52345.

7 Evaluation

The specimen is evaluated in good lighting before and after loading. Any visible changes are detected. The following evaluation system is used for differentiation purposes: Grade 0 No visible change in the surface Grade 1 Visible chisel traces, but no flock abrasion Grade 2 Distinctly visible chisel traces, minor flock abrasion Grade 3 Flock abrasion, but no visible adhesive Grade 4 Flock abrasion, and visible adhesive Grade 5 Abrasion down to the substrate

8 Deviations

The dimensions of the specimens must be agreed and specified in the test reports or test certificates.

9 Referenced documents1

TL 52345 EPDM Body Seals; Quality Requirements TL 52447 Flocking of Interior Trim Material; Material Requirements DIN 50014 Climates and Their Technical Application; Standard Atmospheres

上一篇:轴承滚子缺陷超声波探伤下一篇:几种常用的涂层附着力测定方法和标准

-

上海鼎振仪器设备有限公司

上海鼎振仪器设备有限公司咨询热线 13472521719 内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。上海鼎振仪器设备有限公司 电话:021-32535039 手机:13472521719 地址: 上海市嘉定区德富路1198号803室太湖世家国际大厦

扫一扫,手机浏览

扫一扫,手机浏览