- 技术文章

Ford FLTM BO160-04涂塑料部位高压清洗附着力测试

2019-09-06 08:54:57 来源:上海鼎振仪器设备有限公司

BO 160-04

Application

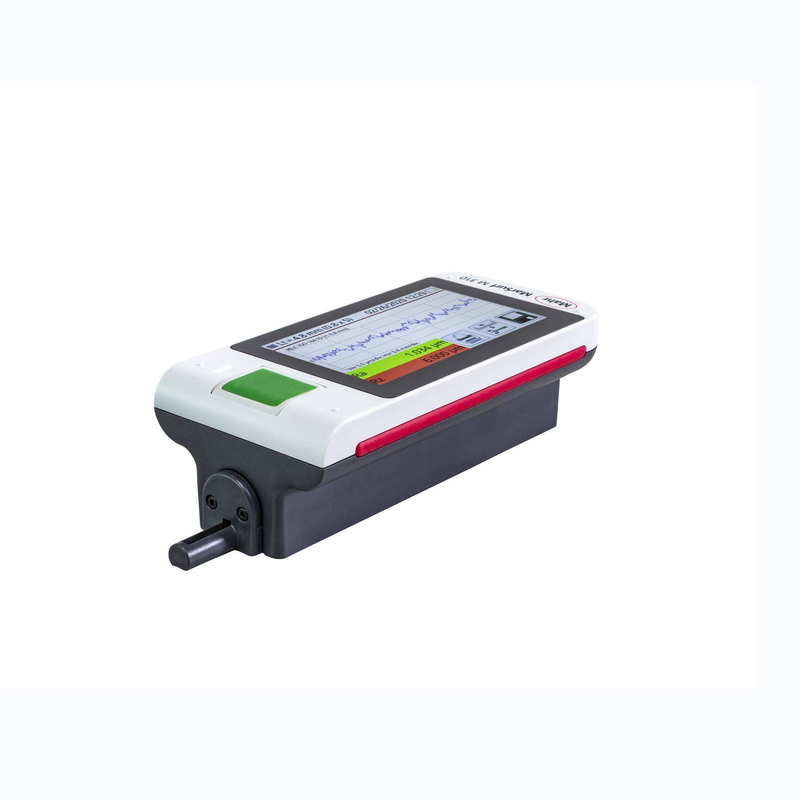

This procedure defines the test equipment and test method for the resistance of painted plastic parts (e.g., bumper bars, mirror housings, radiator grills) against high pressure cleaning processes. Equipment Required

High Pressure Cleaning Equipment:

Cleemax serial 1053

Source:

Pearson Panke Equipment Ltd,

1-3, Hale Grove Gardens,

London NW7 3LR

Great Britain.

Or equivalent instrument suitable to provide the required temperature, pressure and flow rate of water, with a fixed or moving head.

Jet type QVVA 2506

Scriber type:

See FLTM BI 106-1

Settings –

Method A, fixed jet:Jet position Perpendicular to specimen Water temperature 70 °C +/- 2 °C Distance of nozzle to specimen 50mm +/-3mm Water pressure 3000 +/-50 kPa Testing time 60 +/- 3 seconds Water flow rate 420 litres/hour minimum

Method B, moving jet.Jet position Perpendicular to specimen Water Temperature 80 °C +/- 4 °C Distance of nozzle to specimen 100 mm +/-3mm Water pressure 6000 +/-50 kPa Moving range 30mm +/- 10 mm from center,total traverse 60mm Moving cycle 60 cycle/minute Moving direction parallel to the X scribe on the specimen Jet position Perpendicular to specimen (The lines of the X scribe are Northeast to Southwest. The longer axis of the spray fan pattern is East-West, and the direction of movement is North-South.) Testing time 120 seconds, +/-3 seconds Water flow rate 610 litres/hour minimum Note: The water pressure and water temperature settings must be measured immediately behind the nozzle

Conditioning and Test Conditions

All test values indicated herein are based on material conditioned in a controlled atmosphere of 23 +/- 2 °C and 50 +/- 5% relative humidity for not less than 24 h prior to testing and tested under the same conditions unless otherwise specified.

Procedure

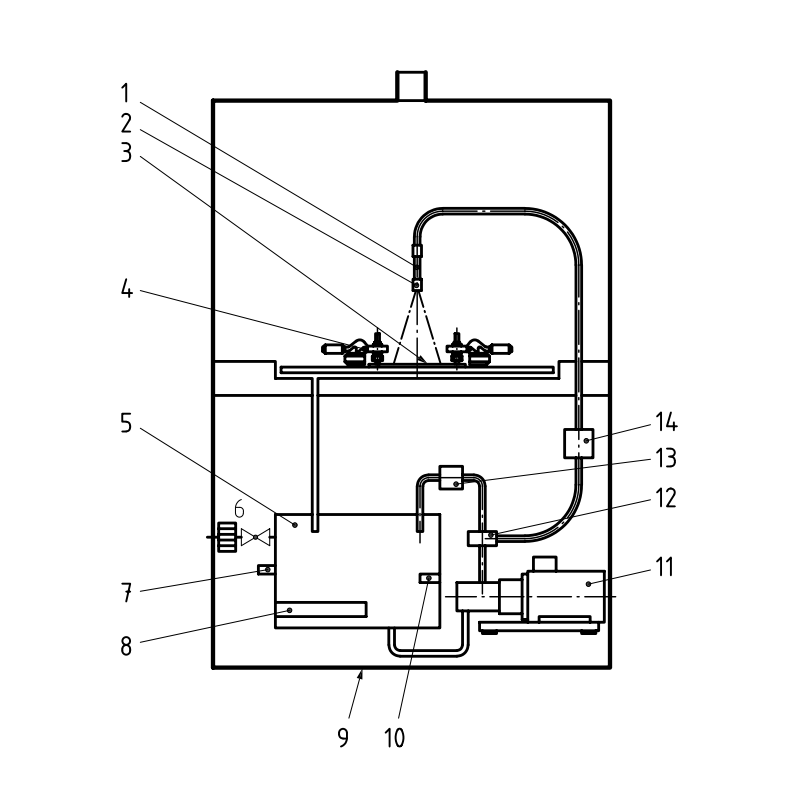

1. The equipment is filled with water without any additional cleaning agents and heated.

2. Before testing the equipment must be adjusted to the required test pressure for the specified distance.

3 Scribe the panel with an X scribe, over the whole area to be exposed to the water jet.

4. The gun with the nozzle is fixed to the required distance from the nozzle to the painted surface which is to be tested. The jet of water has to be directed vertically onto the painted surface.

5. Spray water for the specified length of time.

6. The surface is dried and evaluated after cooling to 23 +/- 2 °C.

7. Report any failure (e.g., loss of gloss, loss of adhesion, surface deterioration). The principal failure mode is paint peeling.

Chemicals, materials, parts, and equipment referenced in this document must be used and handled properly. Each party is responsible for determining proper use and handling in its facilities.

-

上海鼎振仪器设备有限公司

上海鼎振仪器设备有限公司咨询热线 13472521719 内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。上海鼎振仪器设备有限公司 电话:021-32535039 手机:13472521719 地址: 上海市嘉定区德富路1198号803室太湖世家国际大厦

扫一扫,手机浏览

扫一扫,手机浏览