- 技术文章

GMW14872循环盐雾腐蚀试验箱

2017-09-02 11:00:35 来源:上海鼎振仪器设备有限公司

GMW14872

An accelerated laboratory corrosion test to evaluate automotive coatings and components.

Introduction

In 2003 the American Iron and Steel Institute, in conjunction with a Committee of the SAE, conducted a study of existing cyclic corrosion tests in order to establish the best methods of predicting the performance of materials used in automotive applications. Twenty established corrosion test procedures were included within the study. The process itself comprised of undertaking tests on 10 different materials with each procedure, the results were compared to results gathered through real World exposure from 10 locations around the globe, undertaking the tests with identical materials.

The procedures were judged on:

- Their ability to replicate the rank order of coatings performance in the real World.

- Their ability to replicate the same type of failure as viewed in the real World

- Repeatability over multiple tests

- Speed

- Cost effectiveness

The test established that the General Motors standard GM9540P, was one of the best methods of cosmetic corrosion prediction of cold rolled steel and resulted in the publication of it’s successor GMW14872.

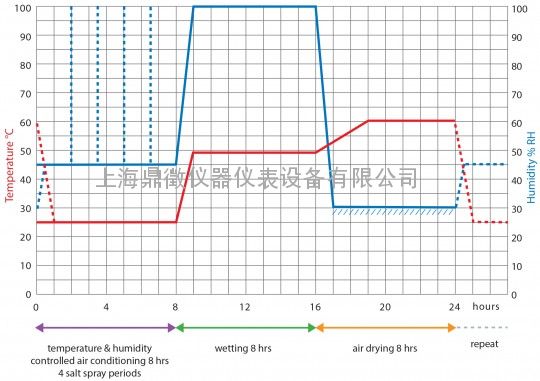

Test Conditions

The test method is composed of approximately 1% NaCL, CaCL2 and NaHCO3 salt mist applications combined with high temperature and humidity drying cycles, a single cycle of the test lasts for approximately 24 hours.

Method

Specimens being tested are exposed to a multi-stage changing environment that is composed of three distinctive cycles, these stages can be varied depending on the nature of the specimen undertaking the test, for further information please refer to the full GMW14872 standard.

The individual cycles comprise of

- An exposure of 8 hours to an ambient climate of between 40 and 50RH% at a temperature of +25C. During this period salt solution is sprayed directly on to the test samples 4 times, for long enough to thoroughly wet them. A minimum of 1 hour spacing between the end of a previous salt application and the following salt application is required. Collection rates for each 80 cm2 of horizontal collection area should be in the range of 0.75 mL/h to 1.5 mL/h.

- An exposure of 8 hours to a water fog humidity climate of 100%RH at a temperature of +49C.

- An exposure of 8 hours to air drying in a climate of <30%RH at a temperature of +60C.

The test length is variable dependant on the number of cycles within the total test duration.

Typical Application

Through analysis of historic data it has been determined that the GMW14872 test process very closely predicts the corrosion rates for steel and zinc materials exposed to periodic de-icing salts, for this reason the standard has become very popular within the automotive industry.

Additionally the US military regularly uses the standard to predict life of a variety of coatings and materials on tactical vehicles.

-

上海鼎振仪器设备有限公司

上海鼎振仪器设备有限公司咨询热线 13472521719 内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。上海鼎振仪器设备有限公司 电话:021-32535039 手机:13472521719 地址: 上海市嘉定区德富路1198号803室太湖世家国际大厦

扫一扫,手机浏览

扫一扫,手机浏览